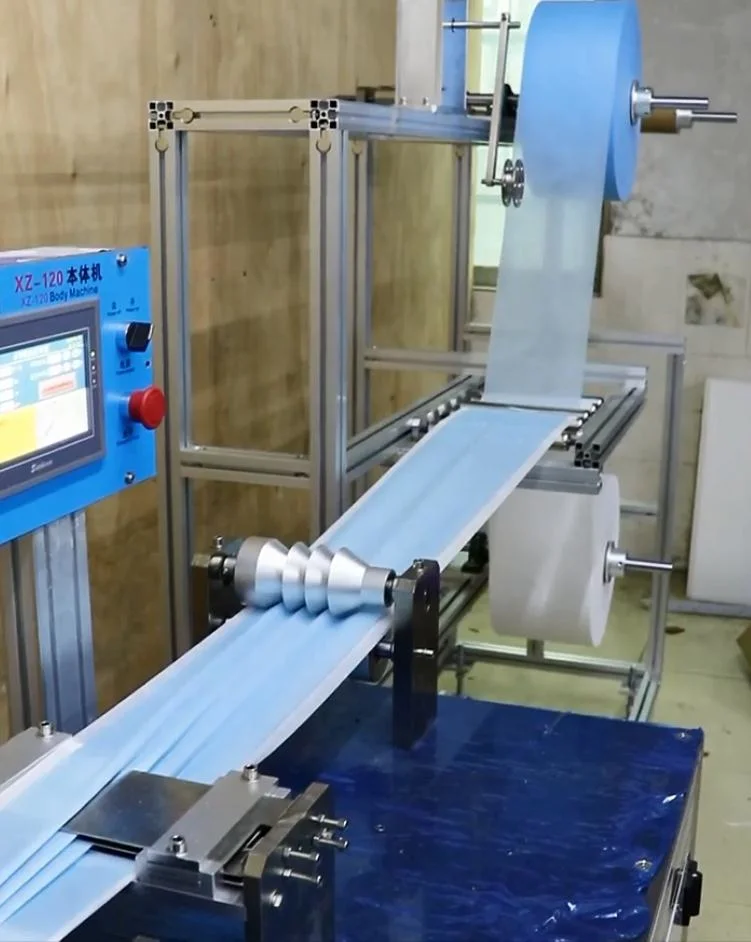

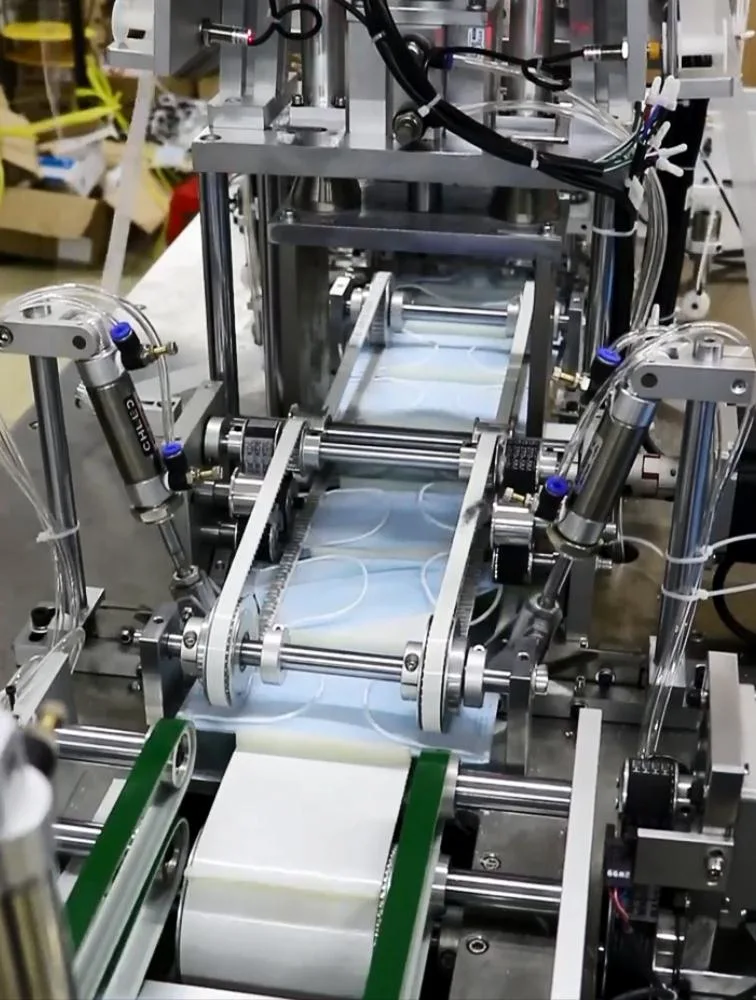

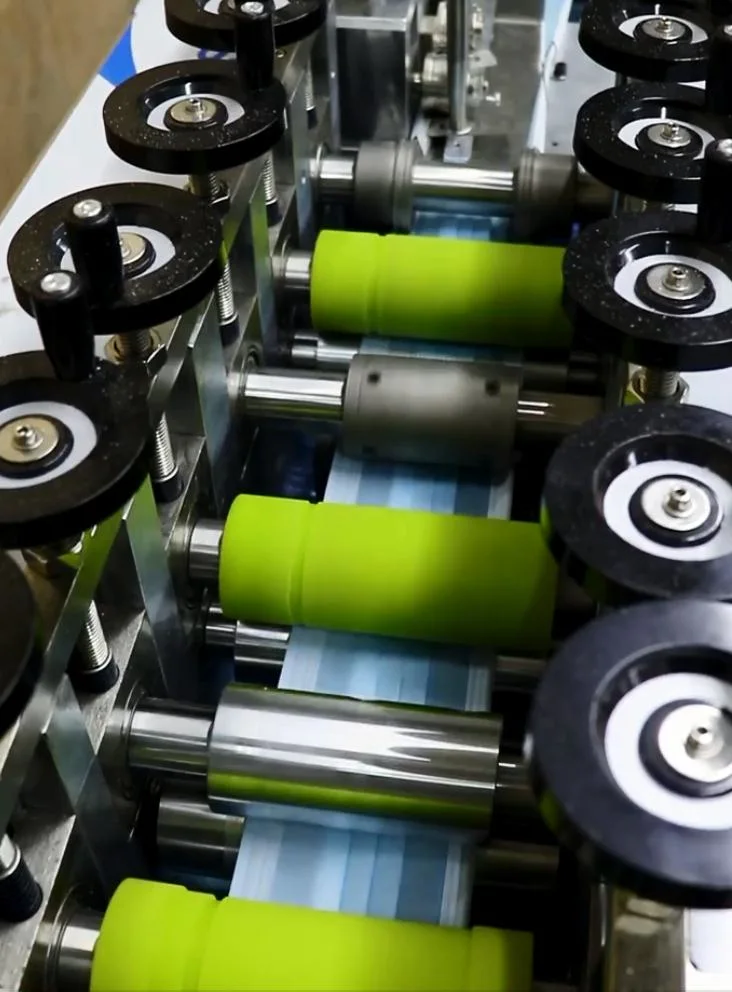

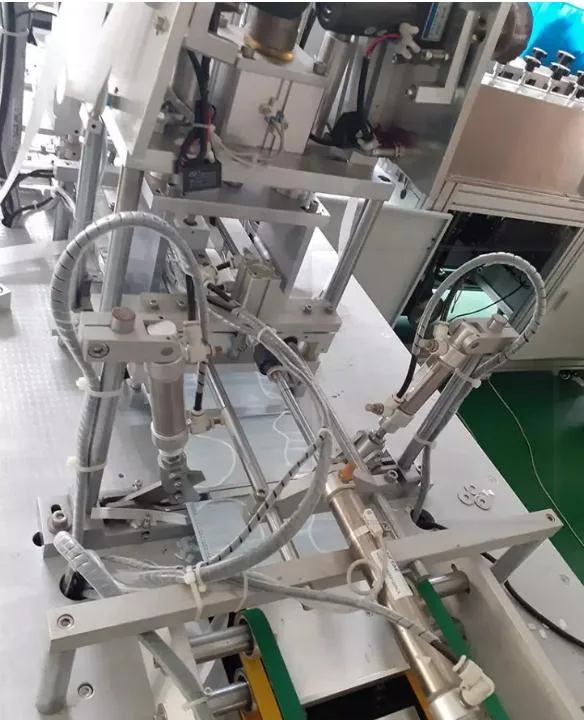

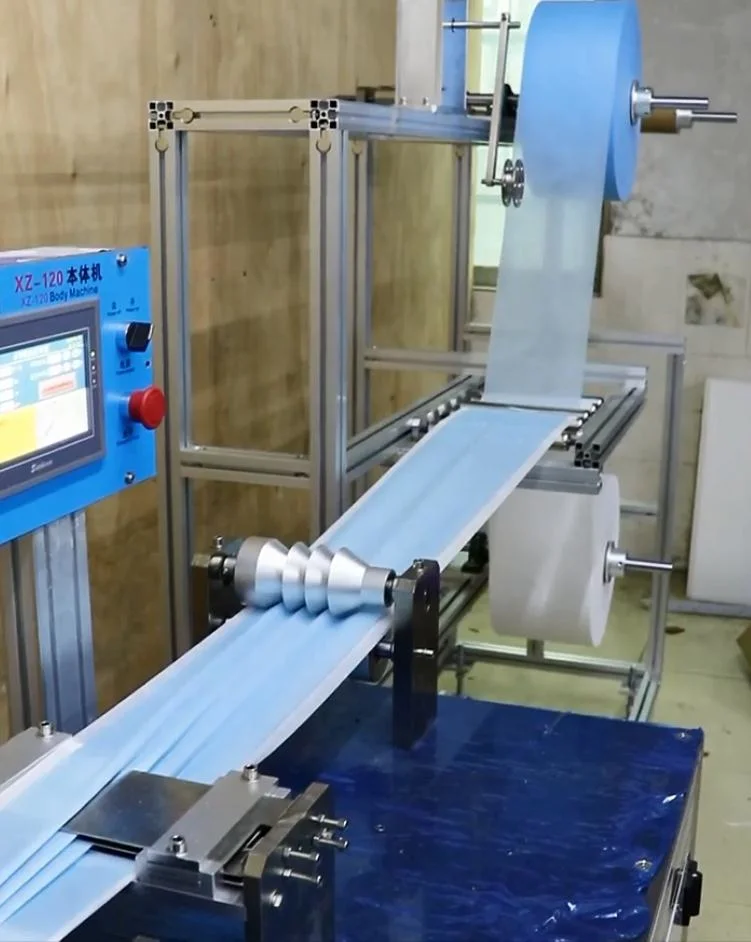

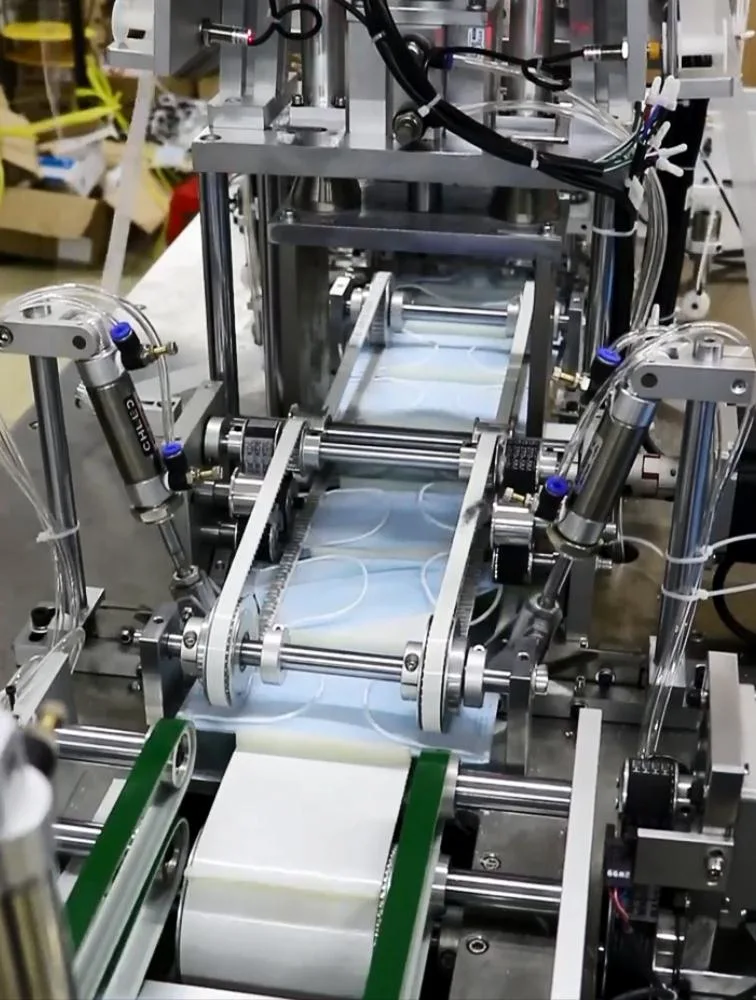

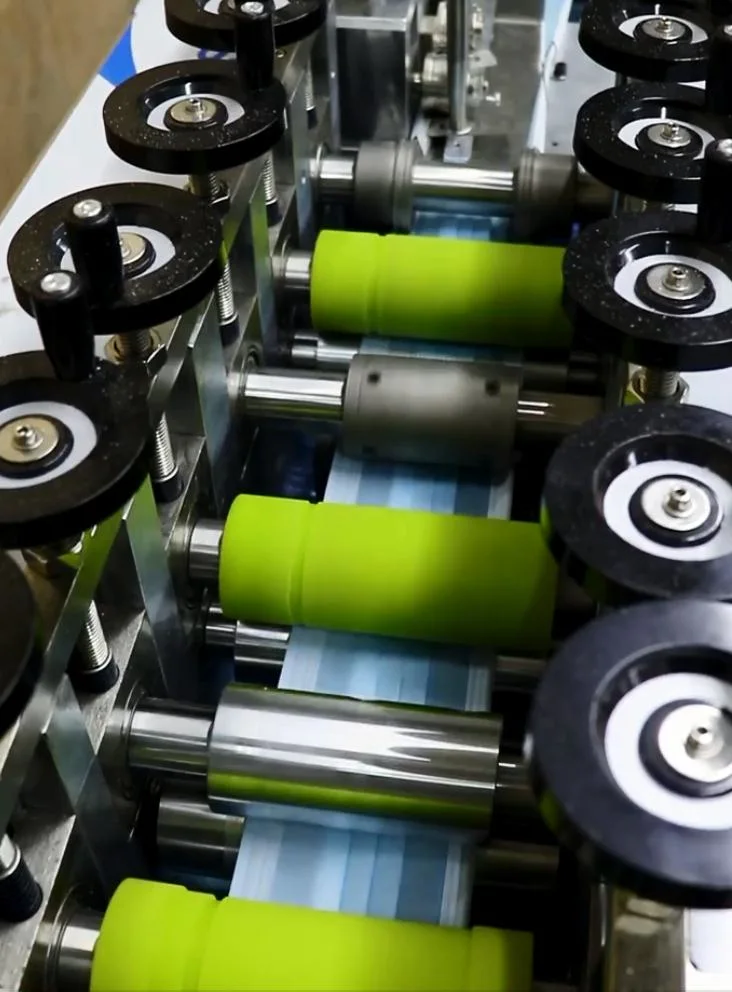

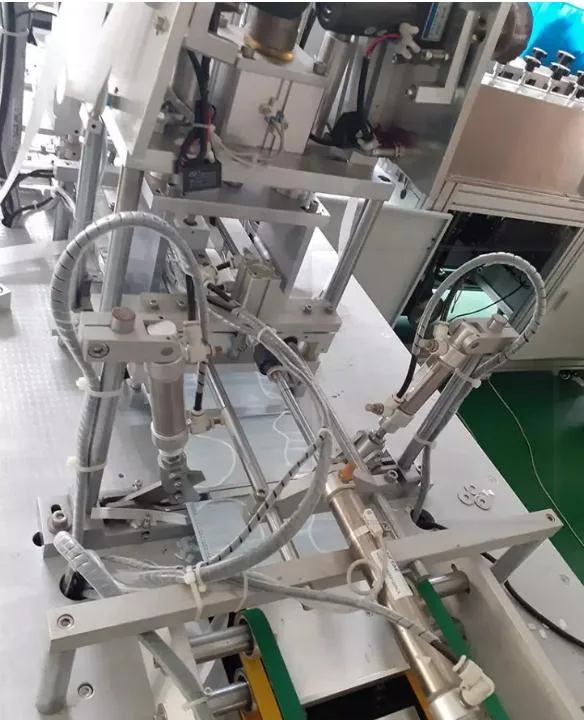

Automatic mask producing line is mainly used for automatic forming of flat masks . After the entire roll of fabric is unrolled, it is driven by rollers , and the fabric is automatically folded and wrapped .Nose bridge rolls unrolled by traction .Cut and import into the hemmed fabric , both sides are welded to seal by ultrasonic welding , and then through the ultrasonic side seal . It is cut and shaped by a cutter ; transported to the two mask ear band welding stations through an assembly line . The final mask is formed by ultrasonic welding. After the mask is made, it is transported to flat belt line and collected.

Suitable material specifications

For more infomation,please contact us.

| Model | FM-002 |

| Size | 5000mm(L)×3500mm(W)×1800mm(H) |

| Mask specification | 175*95mm |

| Production efficiency | 100-120PCS/min |

| Qualification rate | 98-99% |

| Failure rate | 2% |

| Power consumption | About 8.5kw |

| Working power | 220VAC ± 5%, 50z/60Hz |

| Operating environment | temperature 10 ~ 35 ºC, humidity 5-35% HR, no flammable and corrosive gas, no dust (cleanness not less than 100,000). |

Suitable material specifications

| Item | Number of hanging shafts | Width (mm) | Coil outer diameter (mm) | Inner diameter of barrel (mm) | Weight |

| Non-woven Melt-blow cloth | 3 | 170~200 | Φ600 | Φ76.2 | Max 15kg |

| Bridge of nose Steel wire covered plastic / pure steel wire / full plastic | 1 | 3-7 | Φ400 | Φ76.2 | Max 25kg |

| Ear belt | 2 bags | 160*3 | - | - | 10N |

For more infomation,please contact us.