Products Description

Nonwoven Disaposble Medical Face Mask Automatic Earloop Spot Welding Machine Ultrosonic Welding Machine

1. Ultrasonic mask spot welder is a high precision ultrasonic welding machine, which makes the non-woven mask welded firmly.

2. Ultrasonic mask spot welder welding effect is better than ordinary mechanical effect. It is clean and beautiful, is an indispensable tool for production and processing manufacturers.

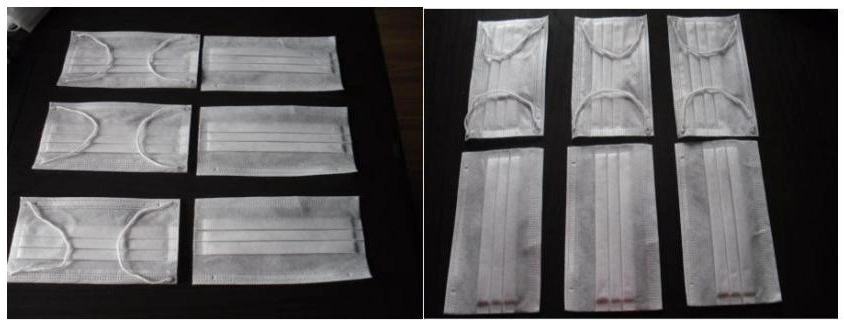

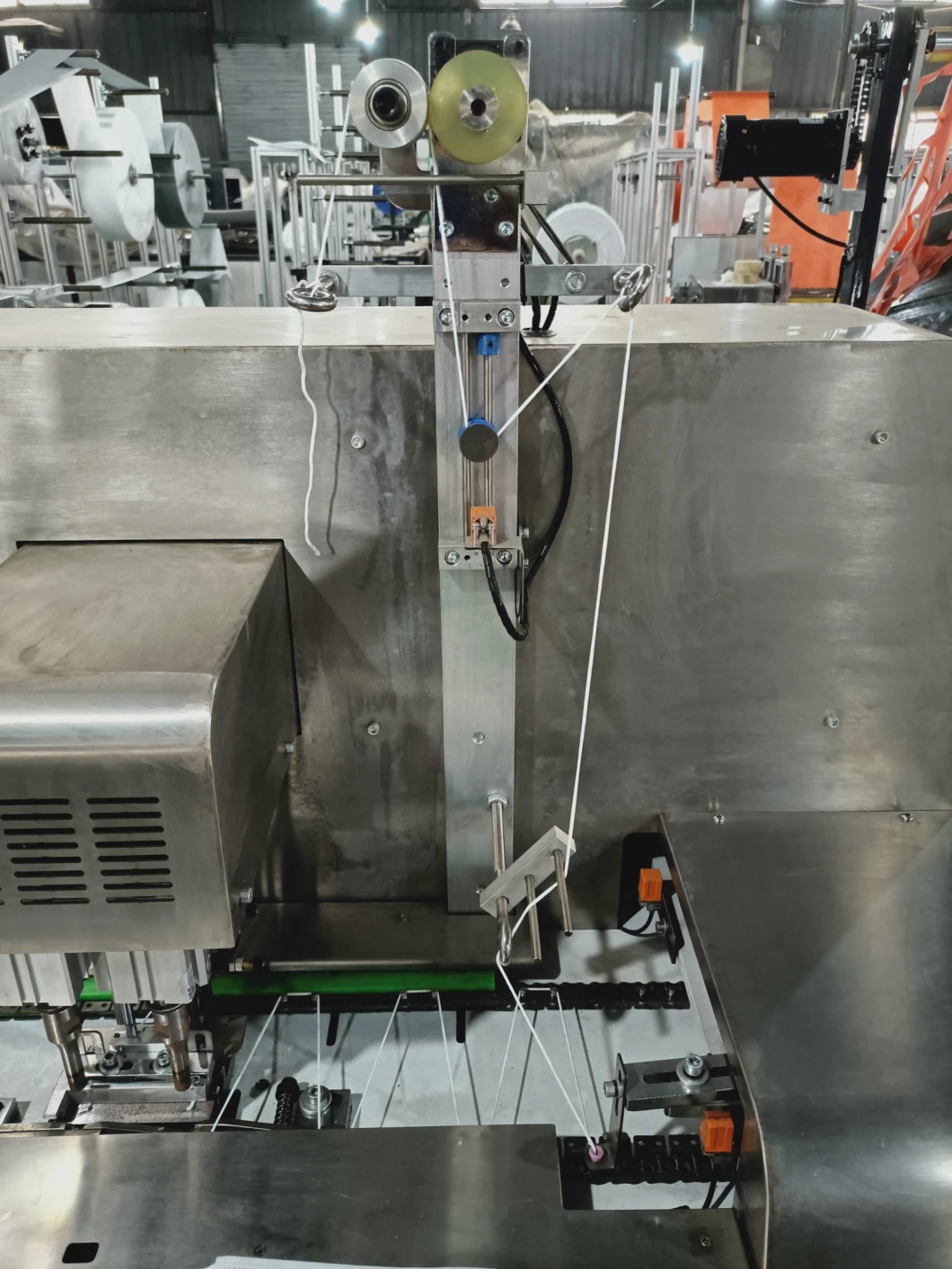

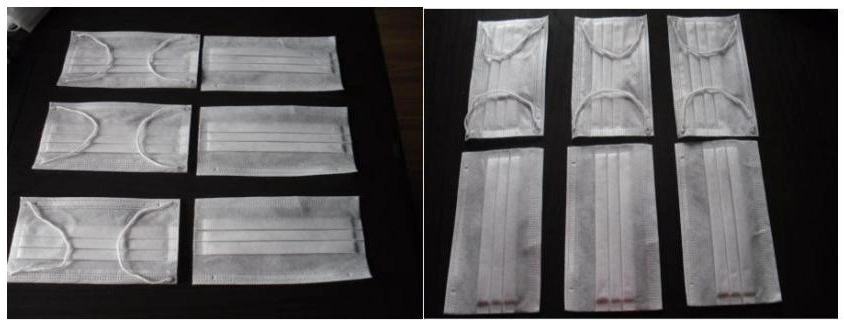

2). Product picture:

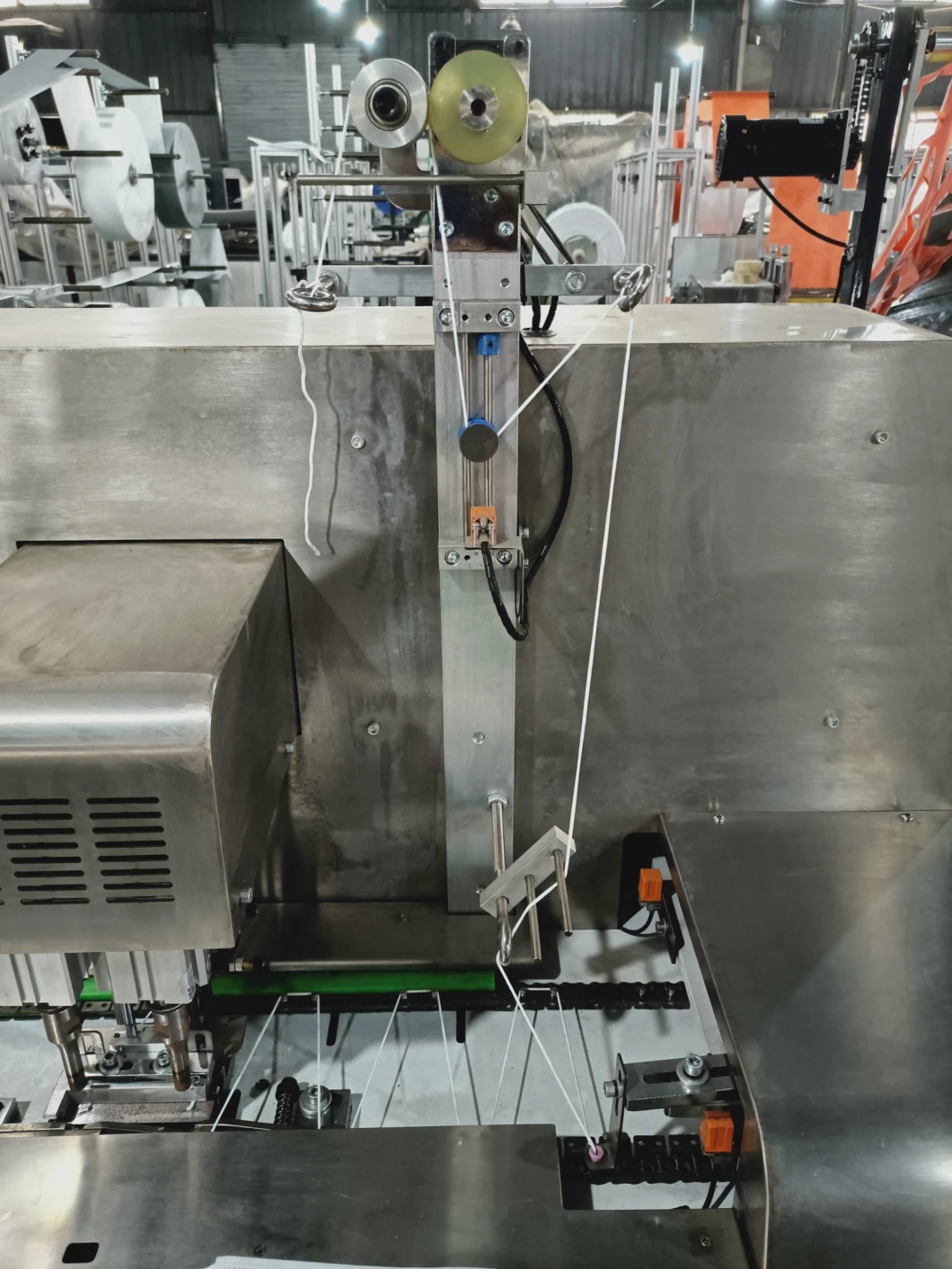

is powerful, up to 1500W, and has the function of regulating large and small p1. The machine is manually operated by one person. The machine is equipped with ultrasonic wave to dissolve the elastic belt on both sides of the mask body, so as to complete the finished product of the elastic belt mask.

2. The machine requires an operator to place the mask body and the elastic belt at each point of the ultrasonic wave at the same time, and the product can be finished by stepping on the switch. Cylinder welding fastness, welding time adjustable, built-in time relay, adjustable air pressure, moderate current regulation, no noise, operation is very simple.

3. Used for chemical fiber cloth, nylon cloth, knitted cloth, non-woven cloth, spray rubber, PE paper, PE+ aluminum, PE+ cloth composite materials.

4. Application examples: lace suit, lace underwear, flower packaging ribbon, tent meeting, raincoat, umbrella, tablecloth, handkerchief, non-woven cloth mask rubber band, diapers, motorcycle cap, non-woven bag, disposable surgical cap, underwear bra welding, and other crafts fusion, pressing, spot welding, embossing.

5. Ultrasonic spot welder adopts original transducer, stable output, high quality component assembly, reliable performance, smart design, easy to operate.

6. Eliminate the trouble of assembling needle, thread and spool of traditional sewing machine, can spot weld the non-woven fabric belt (or other chemical fiber material) on the non-woven fabric bag and the fastness can reach the material strength.

7. High speed continuous operation, high production efficiency, can improve the quality, create profits.

3). Performance and features:

1. The ultrasonic power ower, which can adapt to the welding and cutting requirements of different materials and thicknesses;

2. Multi-channel ultrasonic protection system to ensure the safe and stable operation of the main engine;

3. The rotation function of the bottom die makes the chassis wear evenly, prolongs the service life and improves the processing quality; (lace machine)

4. The machine USES manual welding for rubber belt, which is easy to operate. The machine can be pre-welded according to materials of different thickness. Welding time, avoid manual control of welding, resulting in short time and not firm, welding time is too long, textile damage and other shortcomings.

4). Technical parameters:

FAQ

Q1:Are you manufacturer or trading company?

A1: We are manufacturer with own factory and exporting department.

Q2: What's the lead time of your machine?

A2: Normally it's about 30~45 working days.

Q3: What's the payment terms?

A3: 30% deposit TT, 70% paid before shipment; or L/C, Western Union.

Q4: Can we check machine before order?

A4: Yes, welcome to visit our factory and check machine anytime.

Q5: Is it difficult to install the machine ?

Q5: For standard small machines, the machines will be packed with no take apart, it comes to you to be a complete machine; you

just need to connect power and compressed air to machine, then begin to operate the machine.

For large size machines, we will take the machine apart, on condition that we do our best to keep the machine easy to assembly.

You will get videos and instructions about installation of machine from us.

Q6: Does the machine power voltage meet buyers' factory power source?

A6: We can do it as your request.

Nonwoven Disaposble Medical Face Mask Automatic Earloop Spot Welding Machine Ultrosonic Welding Machine

1) equipment functions:

1. Ultrasonic mask spot welder is a high precision ultrasonic welding machine, which makes the non-woven mask welded firmly.

2. Ultrasonic mask spot welder welding effect is better than ordinary mechanical effect. It is clean and beautiful, is an indispensable tool for production and processing manufacturers.

2). Product picture:

is powerful, up to 1500W, and has the function of regulating large and small p1. The machine is manually operated by one person. The machine is equipped with ultrasonic wave to dissolve the elastic belt on both sides of the mask body, so as to complete the finished product of the elastic belt mask.

2. The machine requires an operator to place the mask body and the elastic belt at each point of the ultrasonic wave at the same time, and the product can be finished by stepping on the switch. Cylinder welding fastness, welding time adjustable, built-in time relay, adjustable air pressure, moderate current regulation, no noise, operation is very simple.

3. Used for chemical fiber cloth, nylon cloth, knitted cloth, non-woven cloth, spray rubber, PE paper, PE+ aluminum, PE+ cloth composite materials.

4. Application examples: lace suit, lace underwear, flower packaging ribbon, tent meeting, raincoat, umbrella, tablecloth, handkerchief, non-woven cloth mask rubber band, diapers, motorcycle cap, non-woven bag, disposable surgical cap, underwear bra welding, and other crafts fusion, pressing, spot welding, embossing.

5. Ultrasonic spot welder adopts original transducer, stable output, high quality component assembly, reliable performance, smart design, easy to operate.

6. Eliminate the trouble of assembling needle, thread and spool of traditional sewing machine, can spot weld the non-woven fabric belt (or other chemical fiber material) on the non-woven fabric bag and the fastness can reach the material strength.

7. High speed continuous operation, high production efficiency, can improve the quality, create profits.

3). Performance and features:

1. The ultrasonic power ower, which can adapt to the welding and cutting requirements of different materials and thicknesses;

2. Multi-channel ultrasonic protection system to ensure the safe and stable operation of the main engine;

3. The rotation function of the bottom die makes the chassis wear evenly, prolongs the service life and improves the processing quality; (lace machine)

4. The machine USES manual welding for rubber belt, which is easy to operate. The machine can be pre-welded according to materials of different thickness. Welding time, avoid manual control of welding, resulting in short time and not firm, welding time is too long, textile damage and other shortcomings.

4). Technical parameters:

| Model | KHJN |

| Total Power | 2.5KW |

| voltage | 220V/50HZ |

| Air pressure | 0.4~0.6Mpa |

| Production speed | 20-30pcs/min |

| Dimension | 1280*750*1500 |

| Machine weight | 300kg |

FAQ

Q1:Are you manufacturer or trading company?

A1: We are manufacturer with own factory and exporting department.

Q2: What's the lead time of your machine?

A2: Normally it's about 30~45 working days.

Q3: What's the payment terms?

A3: 30% deposit TT, 70% paid before shipment; or L/C, Western Union.

Q4: Can we check machine before order?

A4: Yes, welcome to visit our factory and check machine anytime.

Q5: Is it difficult to install the machine ?

Q5: For standard small machines, the machines will be packed with no take apart, it comes to you to be a complete machine; you

just need to connect power and compressed air to machine, then begin to operate the machine.

For large size machines, we will take the machine apart, on condition that we do our best to keep the machine easy to assembly.

You will get videos and instructions about installation of machine from us.

Q6: Does the machine power voltage meet buyers' factory power source?

A6: We can do it as your request.